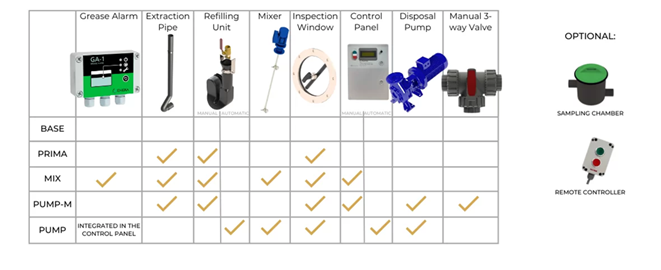

PRIMA Model Provides Odour-Free operation without the need for opening of the cover. The accumulated grease layer can be observed through the inspection window. After reaching level of grease the contaminants are disposed of through the extraction pipe by a vacuum truck. After complete disposal, the separator is filled up with fresh water via the refilling unit by opening the manual ball valve.

After reaching the maximum level of grease the heavy duty disposal pump is activated. The manual switchover valve shall be consecutively switched to positions 1 and 2:

Pos.1 – Mixing: Water with grease and sludge is extracted by the disposal pump from the bottom and delivered to the top of the separator. The heavy-duty pump is breaking the big contaminants into smaller pieces thus facilitating the disposal.

PUMP model is equipped with an autonomous program-controlled emptying system including a disposal pump, a mixer and a grease alarm (integrated in the control panel). A grease alarm is indicating when the maximum level of accumulated grease is reached. The operator activates the automatic disposal mode on the control panel or remote controller(Optional). First of all, the mixer is turned on for blending grease, water and solids. Then the disposal pump is actuated for emptying of the separator